- Home

- »

- Research

- »

- Centers and Programs

- »

- Materials Decarbonization and Sustainability Center

Materials Decarbonization and Sustainability Center

Comprehensive approach to decarbonize building materials.

Learn More

Latest News

New Research Highlights Overestimation of Climate Benefits from Cement Carbonation

A recent study by the UC Davis Materials Decarbonization and Sustainability Center published in Nature Communications has revealed that the climate benefits of cement carbonation, a process where concrete absorbs carbon dioxide from the atmosphere, have been significantly overestimated. The research team of Sabbie Miller, Alissa Kendall, Elisabeth Van Roijen, and Kati Sethares asserts that traditional methods fail to account for the time lag between CO2 emissions during cement production and the much slower rate of CO2 absorption through carbonation. This miscalculation has led to an inflated perception of the technology’s potential to offset emissions and contribute to climate change mitigation efforts.

Learn More

The study emphasizes the importance of considering the full life cycle of cement, including emissions from demolition and the energy-intensive process of crushing concrete. Researchers also highlight the potential of supplementary cementitious materials to reduce emissions and enhance carbonation, while stressing that the primary benefits stem from upfront reductions in production emissions. This important research underscores the need for a more accurate assessment of carbonation’s climate impact and calls for a comprehensive approach to decarbonizing the cement industry.

Read the full report in Nature Communications.

Innovative Recycling Method Could Revolutionize Cement and Steel Industries

Sabbie Miller, faculty director at the UC Davis Materials Decarbonization and Sustainability Center, recently shared with the journal Nature an innovative method to recycle cement and steel together, significantly reducing the carbon emissions associated with these materials. The method involves substituting used cement for lime in the steel recycling process using electric-arc furnaces, which not only helps mitigate the environmental impact of steel production but also creates a valuable resource from waste.

This approach may represent a significant step towards a more sustainable future for both the cement and steel industries, major contributors to global CO2 emissions. The ability to recycle these materials effectively and efficiently has the potential to transform how these industries operate, paving the way for a circular economy model that minimizes waste and maximizes resource utilization.

Read the full report in Nature.

Our Mission

The Materials Decarbonization and Sustainability Center (MDSC) engages in advanced research to tackle the complex challenges of meeting decarbonization goals for building materials. Housed at the University of California Davis, this research hub supports creation of breakthrough technologies (simultaneously addressing material performance and life cycle greenhouse gas fluxes) and links research straight to policy recommendations.

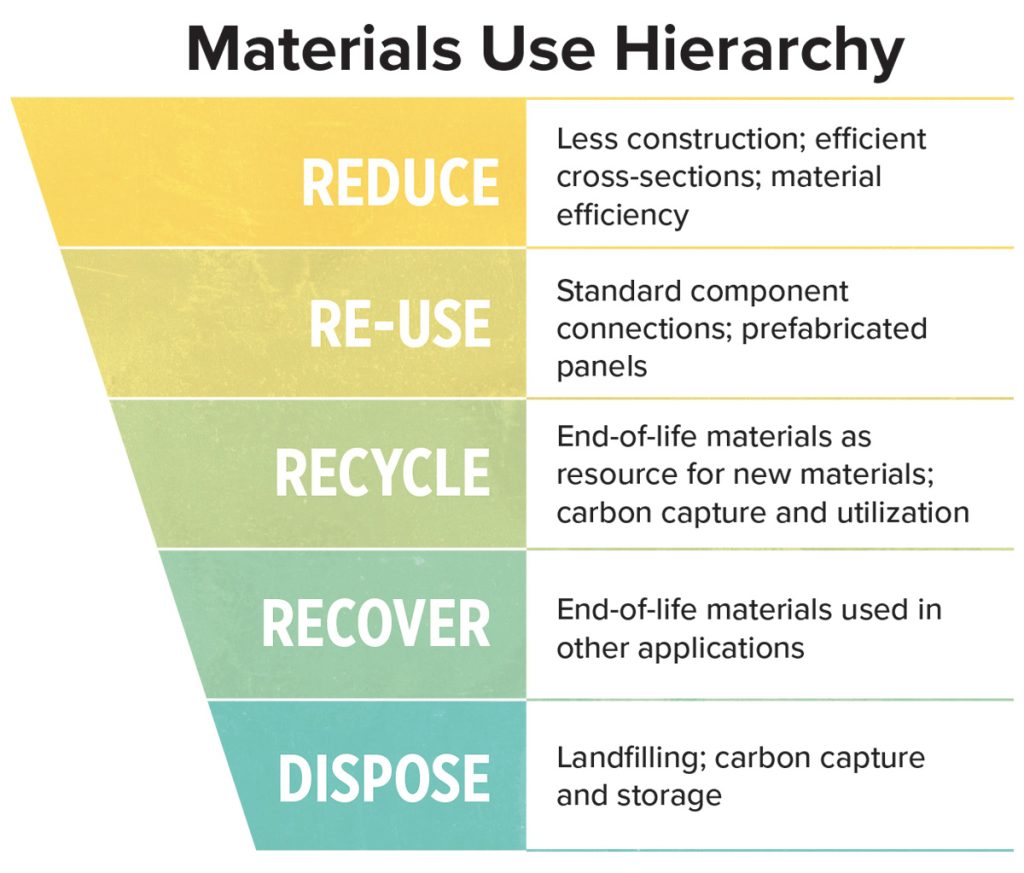

Using a life-cycle approach considering extraction, manufacturing, use, function and end-of-life management to comprehensively address sustainability and functional requirements, this center addresses novel materials development, life cycle environmental impacts, effects on localized resources and populations, policy implications of materials decarbonization, and advancements for current practice (e.g., novel construction methods and engineering code development).

The research hub acts as a catalyst to bring UC researchers across the campus together to develop robust interdisciplinary solutions and connect with relevant industry, government, and non-profit stakeholders. The initiation of this center is laying the foundation for transformative work that will place UC Davis at the nation’s forefront of advanced building materials engineering to counter climate change.

The Materials Decarbonization and Sustainability Center is headed by Professor Sabbie Miller of Civil and Environmental Engineering at UC Davis.

About

Achieving net-zero emissions is critical to avoiding the worst consequences of climate change. This goal cannot be accomplished through reducing greenhouse gas (GHG) emissions alone and will rely on carbon capture and utilization or storage (CCUS). The production of materials has been estimated at ~1/4 of global CO2 emissions, with the majority of these emissions coming from the production of building materials [1]. To overcome these emissions challenges, we must better understand drivers in materials production, their emissions sources, mechanisms to decarbonize conventional materials, ways to engineer low-carbon alternatives, and the economics and policies to help drive implementation.

References:

[1] https://doi.org/10.1038/s41561-021-00690-8

[2] calculated based on cement production from [3] and an estimate that concrete production is approximately 7.5 times larger (note, here we are including all cement-based materials in the term “concrete”)

[3] https://www.usgs.gov/centers/national-minerals-information-center/historical-statistics-mineral-and-material-commodities

[4] https://plasticseurope.org/knowledge-hub/plastics-the-facts-2022/

[5] calculated based on https://rmi.org/wp-content/uploads/2017/04/Pathways-to-Efficiency-in-the-South-Asia-Brickmaking-Industry-Carbon-War-Room_0.pdf ; assuming a brick weighs 2kg

[6] calculated based on bitumen production from http://data.un.org/Data.aspx?d=ICS&f=cmID%3A33500-3 and an estimate that asphalt concrete pavement is approximately AAA times larger